SoWhat wrote:Source of the postCheck with Starlight to see if his silencers are of a similar robustness.

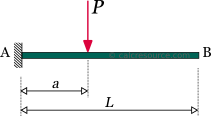

Yes, mine ar two layers of 18mm MDF. As boxes they are sturdy and almost as heavy as Jennifer's but, if I have read and understood correctly, they will be mounted quite differently to mine; it seems that all 50kg will be pulling on the vertical connection and the length of the boxes look long enough that it will create a significant downward force. Something inside me is a bit nervous.

The two main benefits of OSB over MDF or plywood are that OSB-3 is suitable for exterior use and that its shear strength is higher than the alternatives. A minor downside of OSB is I get more splinters in my hands from OSB that any other wood product. Overall I like it and like working with it. I have 36 OSB boards from two deliveries and every one is perfectly flat. MDF has no grain so unless it has bee stored damp it will be fine. Sadly, I like playwood but I have not had a single flat board on this project, every one has been bowed to some extent.

I have 15mm of OSB board above the 2 plasterboard layers on my inner room ceiling which means that anything that hangs from the ceiling is reliant on the OSB's shear strength, of which one silencer box is laid horizontally and has support underneath along only one edge, so the 4 screws holding the other side up are holding up a fair proportion of the 38kg baffle box. For interest, see the nearer silencer in the last photo in post 65 of my build, here. The farther box is held up along two edges and that helps, greatly reducing the downward pull of the box on the ceiling screws.

+1 to Gareth's comment on Jennifer's Sketchup skills.